Revolutionary

Cold and heat insulation

It represents an unparalleled technological advancement in shoe thermal insulation.

Manufacturing method:

It is used as an interlayer, sandwiched between the shoe upper and other materials through lamination or sewing.

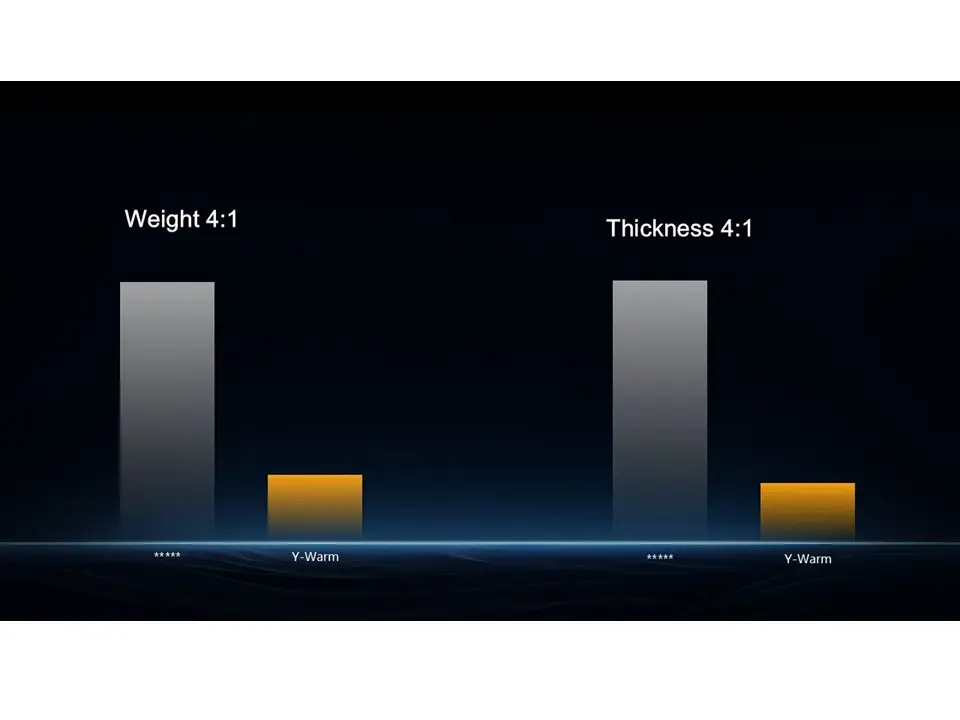

Insulation Performance

Independently certified by a client-hired third party:

Y-Warm and renowned materials were used to make identical-style footwear and apparel for insulation performance comparison; Y-Warm shoes, at just 1/4 the weight and thickness of those made with leading materials, deliver equivalent insulation.

Application Schemes

1. Fabric + Y-Warm + Lining

2. Fabric + Y-Warm + Fleece Fabric

3. Fabric + Y-Warm + Foam + Lining

4. Fabric + Waterproof Membrane + Y-Warm + Lining

5. Fabric + Waterproof Membrane + Y-Warm + Foam + Lining

Lamination Methods

PUR is an advanced and mature lamination process, serving as the optimal solution for laminating Y-Warm with other shoe materials.

Alternatively, low-temperature hot-melt adhesive "web" flat lamination is an option, but it demands advanced lamination skills and strict management. Otherwise, the porous structure of Y-Warm may be damaged.

Precautions

Hot pressing above 100°C flattens Y-Warm holes, which cannot fully rebound.

Higher temperature and pressure exacerbate hole damage.

Ultra-Lightweight

A 50m Y - Warm roll: Light enough for a girl to lift and rotate with one hand.

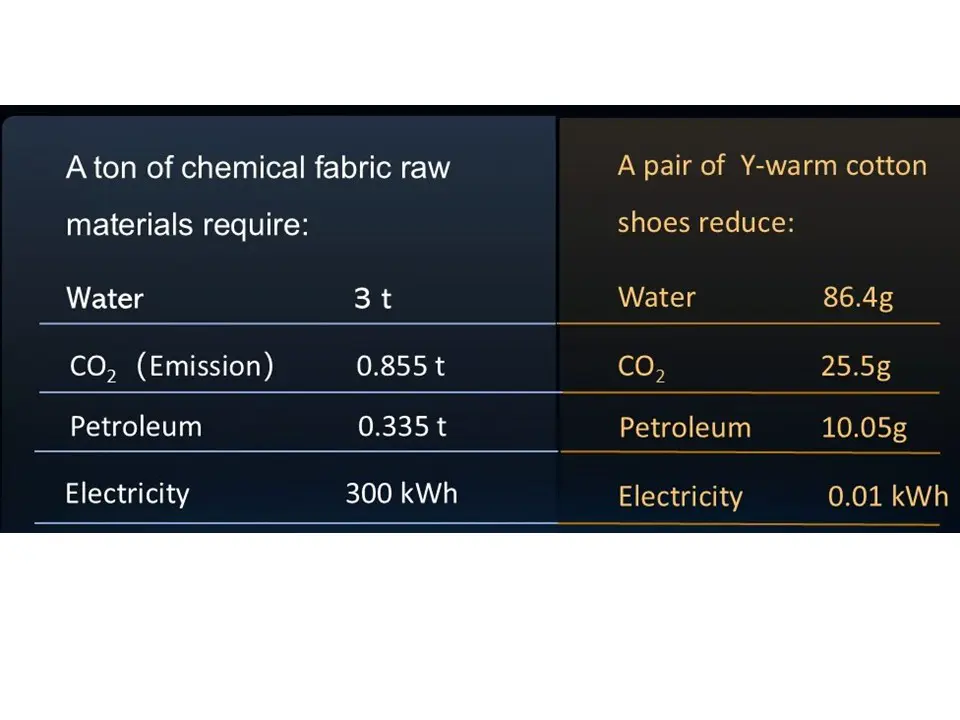

Sustainable

Using the same petrochemical raw materials, Y-Warm achieves the same performance with 1/4 of the weight.

Reducing 75% of resource consumption, it becomes the most sustainable new thermal insulation material for footwear.

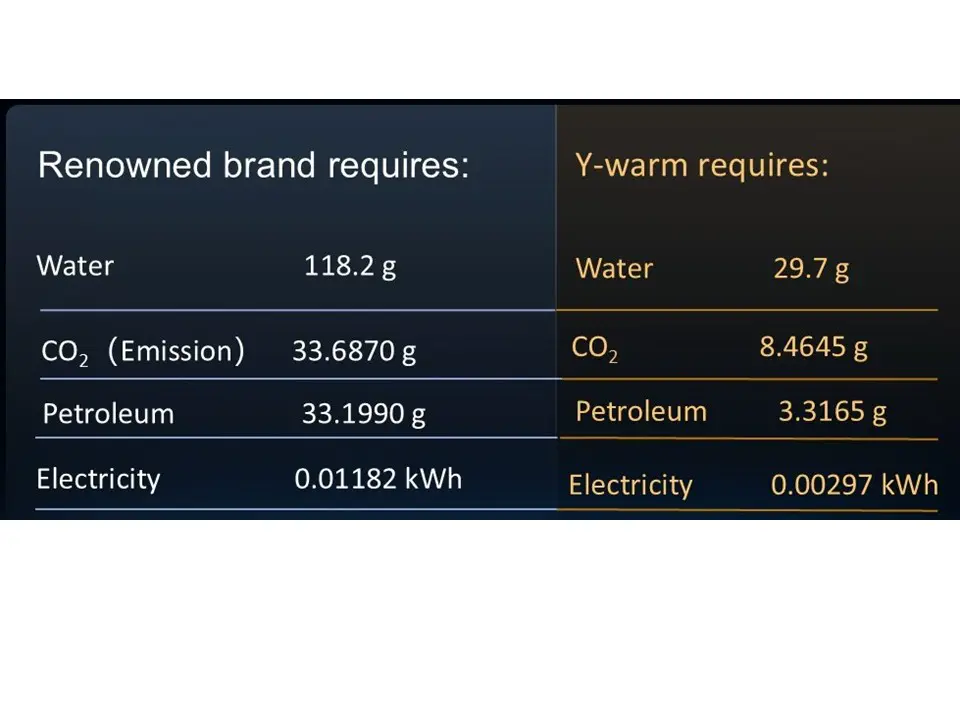

(Sustainable) Reduction comparison

Comparison of resources consumed for the same pair of footwear with the same thermal insulation effect.

Tag

Label the product with the “Technology” attribute.

Woven Label

Label the product as made with technological materials.

Sample package

Display the form of "technology".

Authorization Letter

Patented Innovations® - Legally Protected.